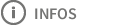

Gripper systems

Precise deposit position and efficient process flows

more Infos...Construction of special purpose grippers

Innovation and technical know-how for your production requirements

more Infos...Vacuum solutions

Special production processes require specific solutions

more Infos...Cutting systems

For the perfect cut

more Infos...Laser-sintering technique

Precise and flexible

more Infos...Conveyor belt systems

The conveyor belt systems of MB Conveyors perfectly complement our product portfolio.

more Infos...Specific solutions

If standard systems are not sufficient ...

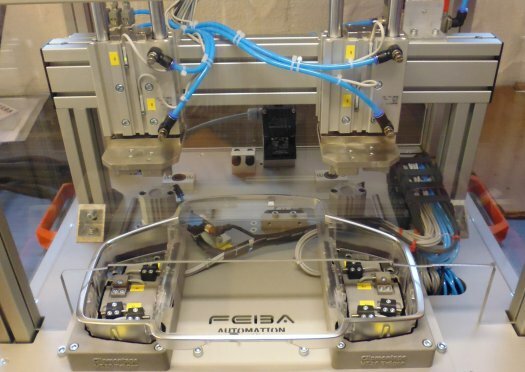

more Infos...Welcome to FEBA AUTOMATION

Your innovative and reliable partner in automation technology

We always make a bit more - so that you are satisfied and have success. Your company needs optimized, accurate and highly efficient solutions? Please contact us! Our highly dedicated team is specialized in automation technology and likes to "think outside the box" for you.

Whether gripper systems, vacuum technology, cutting stations, construction of special purpose machines, feedings or a combination of all these areas. We design and manufacture your automation solution for every task. The long-term partnership with our customers is highly important to us to ensure that we are successful together.

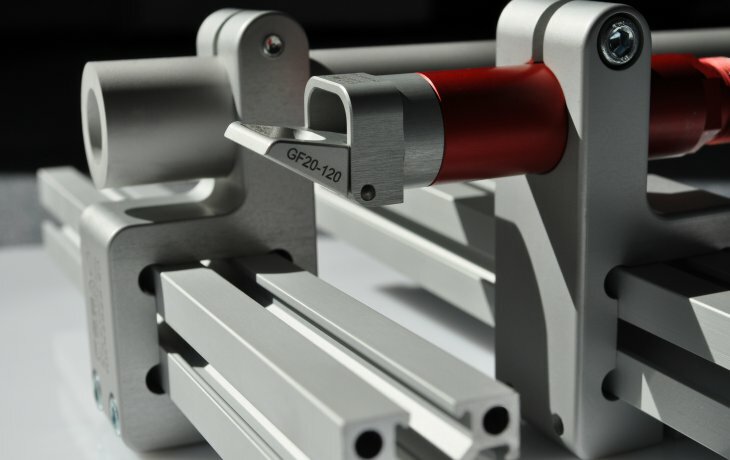

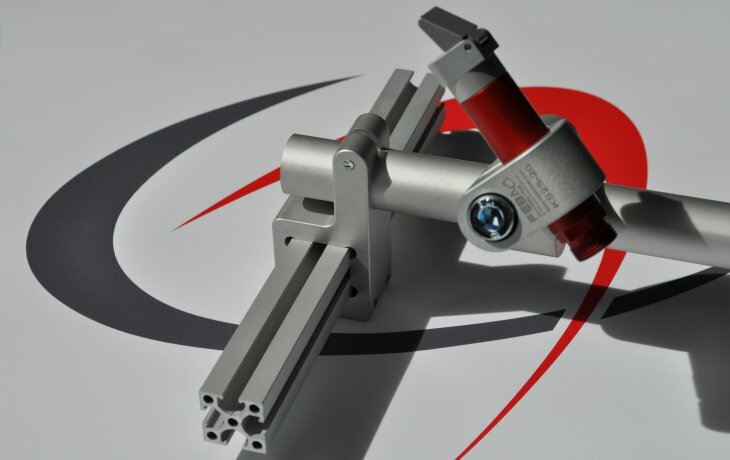

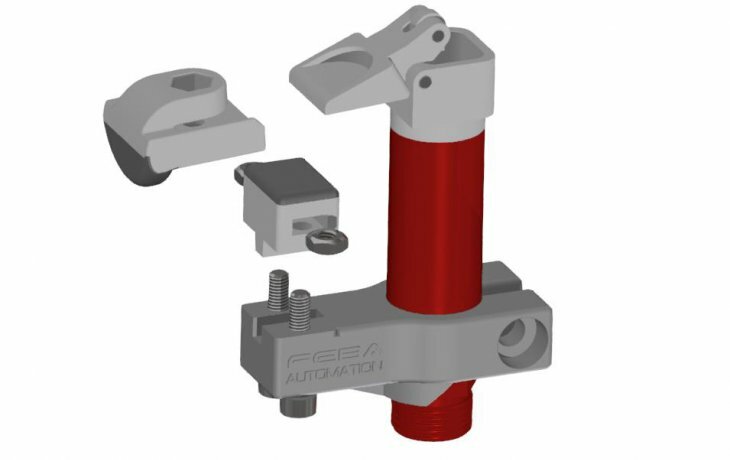

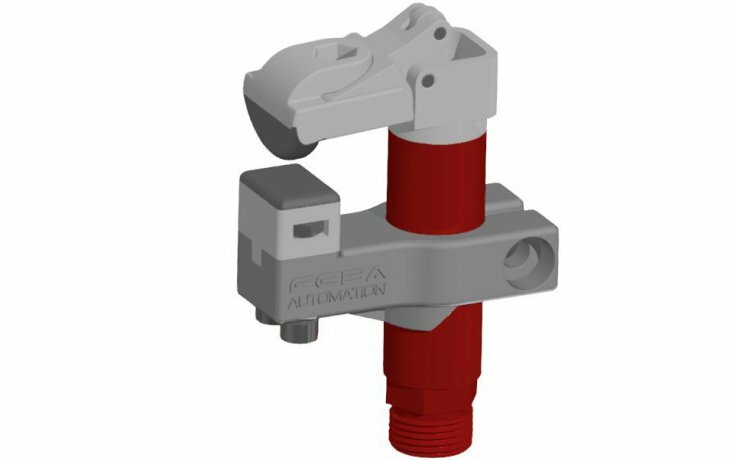

New accessories for gripping fingers GF20 series

FEBA AUTOMATION develops new sensors for special customer requirements

Advantages:

- Easy exchange of the support surface of the 2-part counter holder.

- Gripping finger does not have to be removed from the gripper - reconstruction directly at the removal gripper.

- Position in the gripper system remains - no new adjustment is necessary.

- The support surface can be provided with different geometries.

- In case of wear, only the attachment, not the entire retainer, must be replaced.

- Cost-effective storage.

- Reduction of maintenance and downtime.

Do you also have a special requirement for which the existing standard components are not sufficient? Contact us! Our development and design department will together with you develop an efficient solution.

K2016 – FEBA AUTOMATION international

The K 2016 in Düsseldorf is the world's most important trade fair for innovative applications from the plastics and rubber sector with a high density of decision-makers. This year, 230,000 international trade visitors ensured an excellent atmosphere among the 3,285 exhibitors from all over the world. FEBA AUTOMATION also presented itself at the K 2016 within the context of the future topic "Industrie 4.0" and was able to compete in the international competition with convincing innovations. The response was enormous: The trade visitors were enthusiastic about the high quality of the components of the FEBA AUTOMATION modular system.

Visit us at K 2016 in Düsseldorf 19th-26th October 2016

The latest innovations from FEBA AUTOMATION will be presented at the K2016 - the world's most important trade fair for the plastics and rubber industries.

Meet FEBA AUTOMATION, your partner for automation solutions at hall 08b / booth F39-04! Inform yourself about our range of EOAT, sprue separation, special engineering, vacuum and handling technology.

You are cordially invited. Take the opportunity and visit us at our booth. Do you still need a ticket for the K2016? We would be happy to send you a voucher code for your eTicket for free. Or would you like a personal consultation appointment?

Just call us or write an e-mail to:

FEBA AUTOMATION presents at K2016 "missing link" of two gripper systems

FEBA-FLEX-LIGHT and rectangular system now easily combined

To release well-tried things is hard everyone. This is not different with the construction of EOAT. The so-called square-system has established itself in the market - whether in removal grippers, pick-and-place applications or cutting devices. FEBA AUTOMATION has now developed to the KKX series a compound which allows the user to combine the advantages of the round with those of the rectangular system.

The FEBA-FLEX LIGHT modular system of FEBA AUTOMATION is a cost-effective gripper system on round profile-based, which is characterized particularly by its light weight, easy installation and quick adaptability. The round structure is open, which means hat further components can be added subsequently. Despite the obvious advantages and the steadily increasing demand, a portion of the gripper constructors does still hesitate to completely switch over. Therefore FEBA AUTOMATION has developed, in accordance of the market requirements, the clamping pieces of KKX series, which for the first time enable the integration of the variability of the circular system in the rectangular system. This new product combines the advantages of both systems. The form-fit by "embracing" the APX-profile guarantees a high force. In addition, components such as e.g. Gripper fingers and grippers can be mounted directly.

Aline Urban as "very good trainee 2016" honored by the IHK Arnsberg

On 29.09.2016 our former trainee Aline Urban was honored for her excellent final examination of her training as a businesswoman for office management. For this purpose, the Arnsberg Chamber of Industry and Commerce invited to the Jagdschloss Herdringen. After a photo session the 51 trainees and 15 graduates from the HSK received an honorary certificate and a small present from Mr. Leiße (a member of the plenum as well as the Vocational Training Committee of the IHK Arnsberg). In a "get-together" the graduates were able to exchange their previously collected professional experience.

FEBA AUTOMATION - social commitment for children

With the help of Turnbar by Eiden & Wagner Metallbau GmbH FEBA AUTOMATION had come up with a special fundraising campaign on the occasion of the inauguration of their new premises . At an outdoor horizontal bar a chin-up contest was organized, where every visitor of the event could participate. For each chin FEBA AUTOMATION donated one euro to charity. A proud donation was collected thanks to the active participation and the athletic performance of our visitors. Which afterwards was then still generously rounded. Since the owner couple Bartlewski are especially social commitment to children at heart, two regional charities for children were presented.

Nicole Binnewitt from Children's Hospice Balthasar in Olpe as well as Maria Störmann-Deppe and Petra Schulte from the Kinderburg in Schmallenberg were currently pleased to receive the donation checks.

SWTAL2016 - many visitors and great interest

2450 visitors were counted at the 16th Südwestfälische technology exhibition in Lüdenscheid this year. For FEBA AUTOMATION the fair participation was again a great success - many customers and prospects found their way to our booth to be informed of new developments and the FEBA AUTOMATION modular system. Particularly popular was the new product GZ12-65-65, a gripping plier with rubber jaws. Visitors stated it will expect high acceptance particularly due to its high heat resistance.

FEBA AUTOMATION thanks all visitors for the very positive feedback!

FEBA AUTOMATION thanks for a great day

In perfect weather FEBA AUTOMATION celebrated in Schmallenberg the official inauguration ceremony of the new premises. Under https://youtu.be/Kz4HnApBMVg there are the video to. Take a look! From kart racing, about the acrobatic demonstration of Turnbar teams through to the VLN race car and a very entertaining fundraising event everything was there. The show of the Montotypes and the fireworks were the culmination of a successful party day.

Finally it's done!

FEBA AUTOMATION invites to opening ceremony to newly reburbished premises

Work on the expansion of our premises are completed. And we wish to share the opening celebrations with you. We have therefore pleasure in inviting you to our official

Opening Ceremony

Saturday, 09/03/2016

beginning at 10:00 am

This will be a day of the ‘open door’ whereby you will be able to see for yourselves our 1,000 m² design, assembly, production services and offices all under one roof!

We are looking forward to your visit! Learn about new developments of our company and get to know FEBA AUTOMATION in a relaxed atmosphere!

New gripping plier with rubberized jaws

Available nowt at FEBA AUTOMATION: the gripper Series GZ12 with rubberized jaws for gentle gripping of components. The GZ12-65-65 has Alumide jaws and gumming of Viton, which can be replaced if necessary. Components may be taken up to 160 ° C.

Advantages:

- Simple jaw change by releasing the safety caps

- Jaw movement over two pistons.

- No internal return spring, so no power loss.

- Connection diameter D = 10 mm or M10 x 1

- 100% compatible with popular products

New at FEBA AUTOMATION

Internal project coordinator Lukas van Ackeren

FEBA AUTOMATION sponsor youth team of FC Fleckenberg Grafschaft

FEBA AUTOMATION sponsor jerseys for the children of the F-youth team of FC Fleckenberg Grafschaft. Whether in games or tournaments - FEBA AUTOMATION is always there.

FEBA AUTOMATION sets new standards

New branch office at Reutlingen from 06/01/2016

To be even closer to our customers in postcode area 7 and 8, we are represented in the Grathwohl Straße 5 in 72762 Reutlingen from 06/01/2016. After a 5 - month reconstruction phase, we will be able to rely on a complete component stock and mounting surface. Of course we support you in matters relating to the EOAT - any time, even on site.

We look forward to you!

Podium for WS Racing

On Thursday, 26 May 2016, the WS Racing team made its way to the famous 24-hour race at the Nürburgring. The expectations of the team, again to achieve a similarly good result as in previous years, could well be fulfilled. At the end of the 24-hour race on May 29, 2016 WS Racing could occupy the 3rd and 5th place in the Cup Astra class.

The weekend at the Nürburgring was already quite mixed for racers of WS Racing teams at the start. Even in the pre-qualification, there were technical problems repeatedly. The Opel Astra OPC Cup with the start number 253 had just before the race even an electronics problem that could be solved but thanks to the professional use of the technicians seconds before the start. Even during the race drivers Ralf Lammering, Bernhard Henzel, Stephan Kuh and Jean-Luc Behets struggled with adverse incidents: Twice the car was shot down by an Audi R8. Fortunately, the race both times could be continued without any major difficulties. Finally, the pilots were able with their offensive driving style even fight his way back to 3rd place. In total ranking, the team was able to record the 57th Place.

The second race car, piloted by Fritz Rabensteiner, Tatjana Hanser, Christoph Hewer and Uwe Stein, starting with the number 254. The team was constantly on the road and kept as much as possible from collisions out. Only once it was pressed against the guardrail. The weather conditions made to provide: After one hour, the race had to be interrupted for about three hours due to rain and strong hail. At the end of the team in the Cup Astra class landed on 5th place in the overall standings at the 87th rank.

Team boss Thorsten Willems sees the team performance this emotion-rich race very positive, as the team already went back to the podium for the third time in a row after the class win in 2014 and, 2015. Honor and gratitude not only the entire team to all sponsors, partners and supporters.

Photos by Daniel Koerlings

FEBA AUTOMATION continues to grow

Doubled production and office space

The quality of products from FEBA AUTOMATION secret anymore - for commissioning traveling our service technicians now throughout Europe, China and Mexico. With this growing success and steadily increasing number of employees and the space grew. In the spring of 2015 was therefore started with the expansion of the company building. During operation, an entire floor was "draufgesetzt". Thus, the production and office space could be doubled to approximately 1000 m². For 2016, the extension machinery now is scheduled to meet customer requirements continue to meet.

Video documentation of reconstruction:

rescued first points on the line

Turbulent start to the season of the VLN

At the first race of the VLN, the 62nd ADAC Westfalenfahrt, the WS Racing Team starts with little luck in the season. Even when training the Blue Cup 2 crashed so strong that the front bumper and a fender had to be replaced and only belatedly could start the race. Cup 1 with driver Jens Rarbach lost already after a short course of the race at a blameless collision with another car, the rear bumper and was later damaged again by a bump of another race participant at the driver's door. That the two Opel Astra OPC have ever seen the goal and could enter the first points of the season, only thanks to a huge team effort of drivers and technicians was possible. The disappointment over this bumpy start was Jens Rarbach clearly noted: "It was clear that we can not expect too much in this new competition with a high proportion of professional drivers and with the new car, but I had hoped for more today. Our Astras were well adjusted and were actually super ride. But we must now look ahead and prepare for the next race."

Preparations for season start

The start of the season in 2016 at the Endurance Championship Nürburgring is imminent. The team WS Racing presented a few days ago before the finished race car. FEBA AUTOMATION will be seen in prominent placements on the vehicles. First test drives are already done. But until the first race on April 2, the technical team will have a lot to do.

FEBA AUTOMATION in the season 2016 at the Endurance Championship Nürburgring

Since 2014 FEBA AUTOMATION is sponsoring the racer Jens Rarbach, who currently went from the ADAC Youngtimer Trophy to Endurance Championship Nürburgring. The VLN is considered to be the most popular national racing series and is a real crowd puller. FEBA AUTOMATION makes this climb with love and accepts the change to team WS Racing as an opportunity to introduce Jens Rarbach.

FEBA AUTOMATION talking to Jens Rarbach

FEBA AUTOMATION: How did you ever come forward to become a racing driver?

Jens Rarbach: Racing, I always thought, since I can remember, is the greatest! For me there was never anything other than cars. Especially the competition with any type of vehicle has always fascinated me.

FEBA AUTOMATION: Is it a matter of priority to speed, competition or cars?

Jens Rarbach: Exactly the mixture is that fascinated me so much. But I do not think about this. That's more of a feeling. I just love it!

FEBA AUTOMATION: Why have you changed your team?

Jens Rarbach: Because it is simply a climb for me. It is more professional. The whole racing league is professional. We have professional racer, therefore the competition is much stronger. What particularly excites me: the cars are identical, the technical requirements are the same for all - that means, it really depends on the driver.

FEBA AUTOMATION: New competition, new team, new car - what do you expect of the upcoming season?

Jens Rarbach: At this kind of endurance race a car is shared by a team of drivers. It is important that each driver is fast but also constantly driving. My new team WS Racing will have three good drivers run one car and will also give the best possible technical support in order to get top-placements. My aim is to get one of the top places even in the first season. Finishing in the top five is possible. You also get in the VLN much more attention. About 100.000spectators visit the races during one year an they are broadcasted regularly on TV. And of course, I am looking forward to ten exciting races in a 320-horsepower car! Come and visit me at a race! Then I show you the pits and the paddock. I bet that you no longer can escape from racing fever!

FEBA AUTOMATION: We definitely will do and good luck in the upcoming season!

Events 2016:

02.04. 62. ADAC Westfalenfahrt

30.04. 41. DMV 4-Stunden-Rennen

14.05. 58. ADAC ACAS H&R-Cup

25.06. 47. Adenauer ADAC Deutsche Payment-Trophy

16.07. 56. ADAC Reinoldus-Langstreckenrennen

20.08. 39. RCM DMV Grenzlandrennen

03.09. ROWE 6 Stunden ADAC Ruhr-Pokal-Rennen

24.09. 48. ADAC Barbarossapreis

08.10. DMV 250-Meilen-Rennen

22.10. 41. DMV Münsterlandpokal

Fair TechniShow 2016

March 15 to 18, 2016 (Hall 11, Booth G034)

Visit us on the TechniShow in Utrecht from 15 to 18 March 2016. We are looking forward to meet you !

First apprentices from FEBA AUTOMATION has passed her final exams with flying colors

Aline Urban has passed in January 2016 her final examination as clerk for office management with an excellent result. Particularly noteworthy, since she had shortened her training period to two and a half years. In the company's history of FEBA AUTOMATION is the first apprentice. On behalf of everyone congratulated CEO Jürgen Bartlewski, the young office clerk and is particularly proud that Aline Urban remains the FEBA AUTOMATION continue to receive. You will be working in the accounting department of the company in the future.

FEBA AUTOMATION supports the DKMS in the fight against blood cancers

|

We promote the DKMS German Bone Marrow Donor nonprofit mbH and thus their vital task, to win as many people as living donors for blood cancer patients. Instead of the usual Christmas presents we donate the intended amount and support the DKMS thus the fight against blood cancer!

Certified quality at FEBA AUTOMATION

according to DIN EN ISO 9001

Since 2012, the FEBA AUTOMATION is certified according to DIN EN ISO 9001. Currently the development, production and business processes of the company have been successfully subjected to recertification.

The quality management system is a key component of our quality policy - so that we can make sure that the continuous development of FEBA AUTOMATION quality standards is lived every day. With the constant analysis of business processes FEBA AUTOMATION ensures the continuous optimization of products and services - in the interests of our customers.

FEBA AUTOMATION optimizes Gripping Pliers GZ20 with Sensor

Improved sensor sensitivity and modular connectivity

Advantages of the new gripping pliers GZ20 with sensor:

- Sensor to complete baking width

- Pressure plate not screwed , but floatingly

- Pressure plate grip by ribbing

- Multiple connection options for compressed air

- securing the dowel pins on plastic cover plate , characterized simpler changing of jaws possible

- Modular connectivity options: either screwed directly on a plate

Would you like to see the advantages of the new gripping pliers GZ20 yourself?

Ask for a free sample for 4 weeks and test it yourself!

Questions about our new gripper or other products of FEBA AUTOMATION ? Give us a call:

Sarah Brinker

Vertrieb Innendienst

t. 004

f. 004

Our sales team will gladly give you advice or make an appointment with your local sales office.

FEBA AUTOMATION - We grow for you!

To enable us to more efficiently fulfill the needs and requirements of our customers, we enlarge our production space at the site Schmallenberg to 1000 m².

With the spatial expansion, we make room for the expansion of the following departments :

- Pre-assembly , assembly and manufacturing

- Development / Engineering

- Design and Sales Office

We are training!

Peter van Lottum begins training as a milling machine operator

On 1st August 2014 Peter van Lottum started his apprenticeship as a milling machine operator at the FEBA AUTOMATION & Modular Systems GmbH. We are glad about our new team member and wish a good start in his career!

Sponsoring

We support motor sport

FEBA AUTOMATION sponsors the motor sport team of Fleper from Lennestadt.

(Tipp: between seconds35 und 55 FEBA AUTOMATION is fully in the picture!)

Innovation made by FEBA AUTOMATION

Gripping finger with a pivoting angle of 120°

Absolutely innovative is the new patented gripping finger of the 20 series. With a pivoting angle of 120 ° it opens new worlds.

A "snagging" of plastic components is not possible with this technique. With this new product from FEBA AUTOMATION we have again demonstrated our innovation capacity. The new gripper is becoming a "hit" in the market for gripper construction. You are interested? Go and see for yourself and request the product for 4 weeks free of charge.

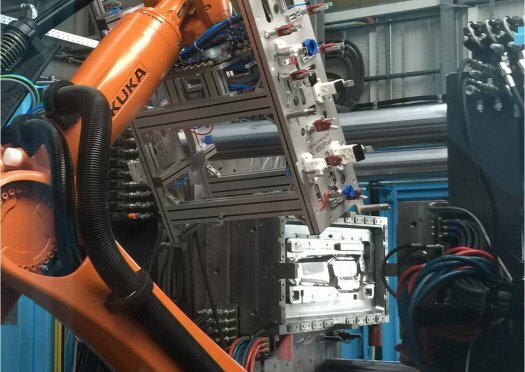

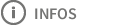

Gripper systems

Precise deposit position and efficient process flows

The gripper systems developed by FEBA AUTOMATION are completely flexibly combinable and are an important interface between robot and product.

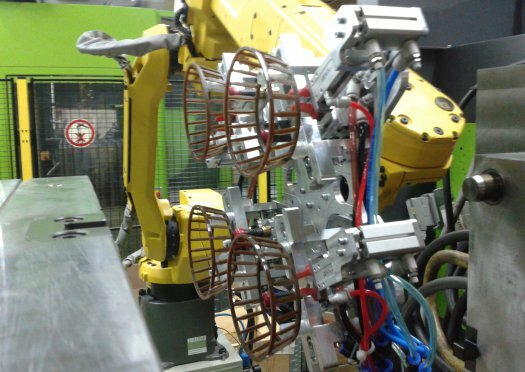

Vacuum solutions

Special production processes require specific solutions

System solutions from FEBA AUTOMATION in the field of vacuum automation allow gripping, lifting and height compensation of almost all types of production parts. For many different industries and tasks, the innovative vacuum components are an ideal option. Whether uneven, porous, rough or curved surfaces, different heights or for the handling of bags - for each of these requirements we are able to construct a solution that optimizes your production processes and speeds.

Construction of special purpose grippers

Innovation and technical know-how for your production requirements

Cutting systems

For the perfect cut

The sprue separation or contour adaptation of your components will be optimized with our cutting pliers and cutting inserts.

Laser-sintering technique

Precise and flexible

With the laser-sintering process we perfectly complement our product portfolio in order to solve complex tasks defined by our customers.

Conveyor belt systems

The conveyor belt systems of MB Conveyors perfectly complement our product portfolio.

With this high-grade range of conveyor belts we are able to offer you individual solutions for feedings as well as suitably complete complex production solutions.